K1st BUILD

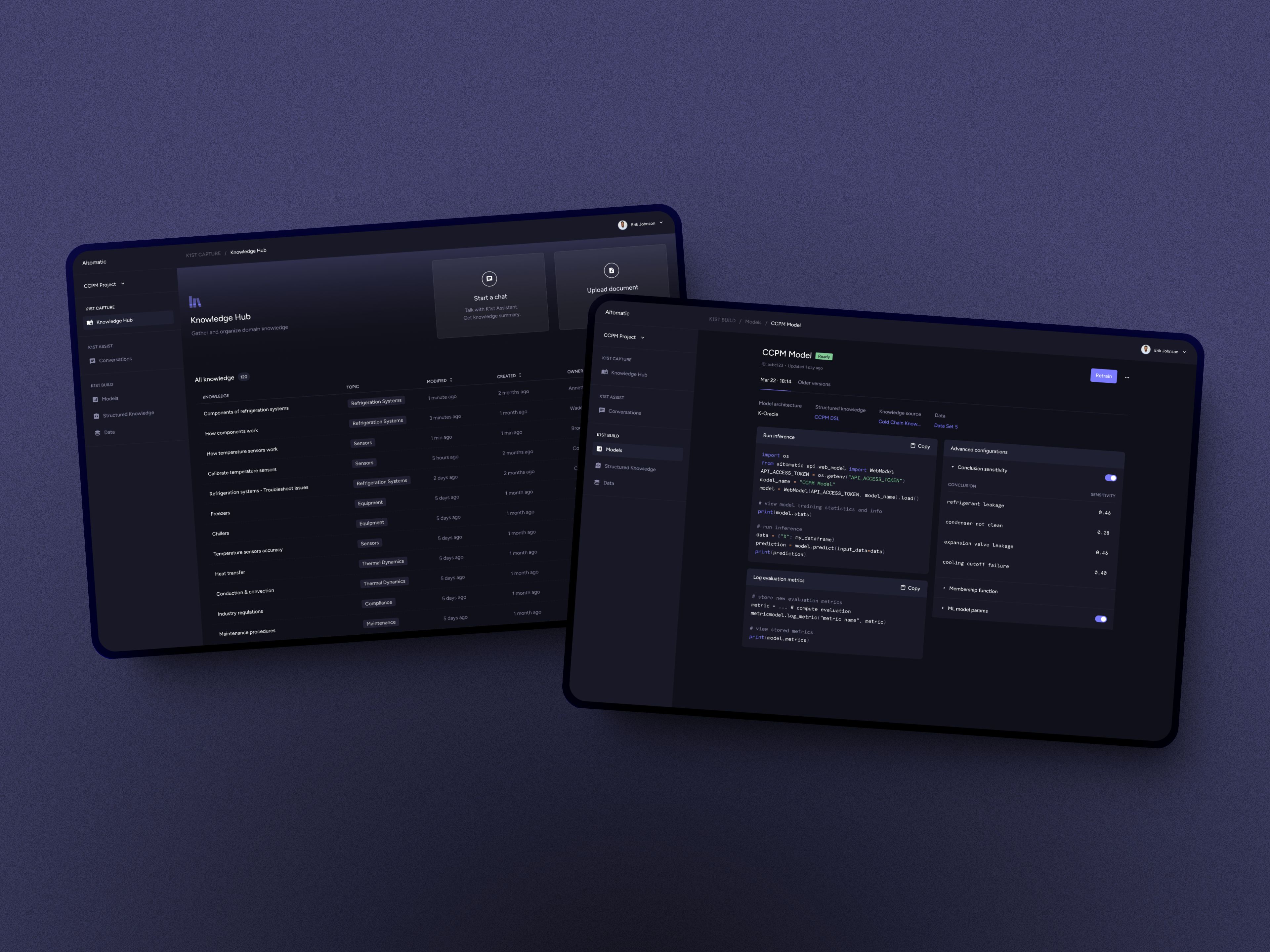

Build AI models from human knowledge

Problem

Manufacturing companies struggled to build AI models due to incomplete datasets, requiring significant time for data preparation and delays in operations.

Solution

We created K1st BUILD — a knowledge-first AI model building app to use knowledge from experts, reducing reliance on datasets while speeding up model development.

Reduced data prep time by 30%

Improved model accuracy by 15%

Company

Aitomatic

Position

Founding Designer

Year

2022 – 2023

Market

APAC & US, B2B

Problem

Building AI models in manufacturing is harder than it sounds. Unlike industries with clean, abundant data, manufacturing datasets are often messy, incomplete, and unreliable. Engineers spend weeks piecing together scattered information just to prepare the data, delaying model development and risking costly downtime.

The challenge was clear: how could we help companies build AI models faster, even when the data wasn’t perfect?

Solution

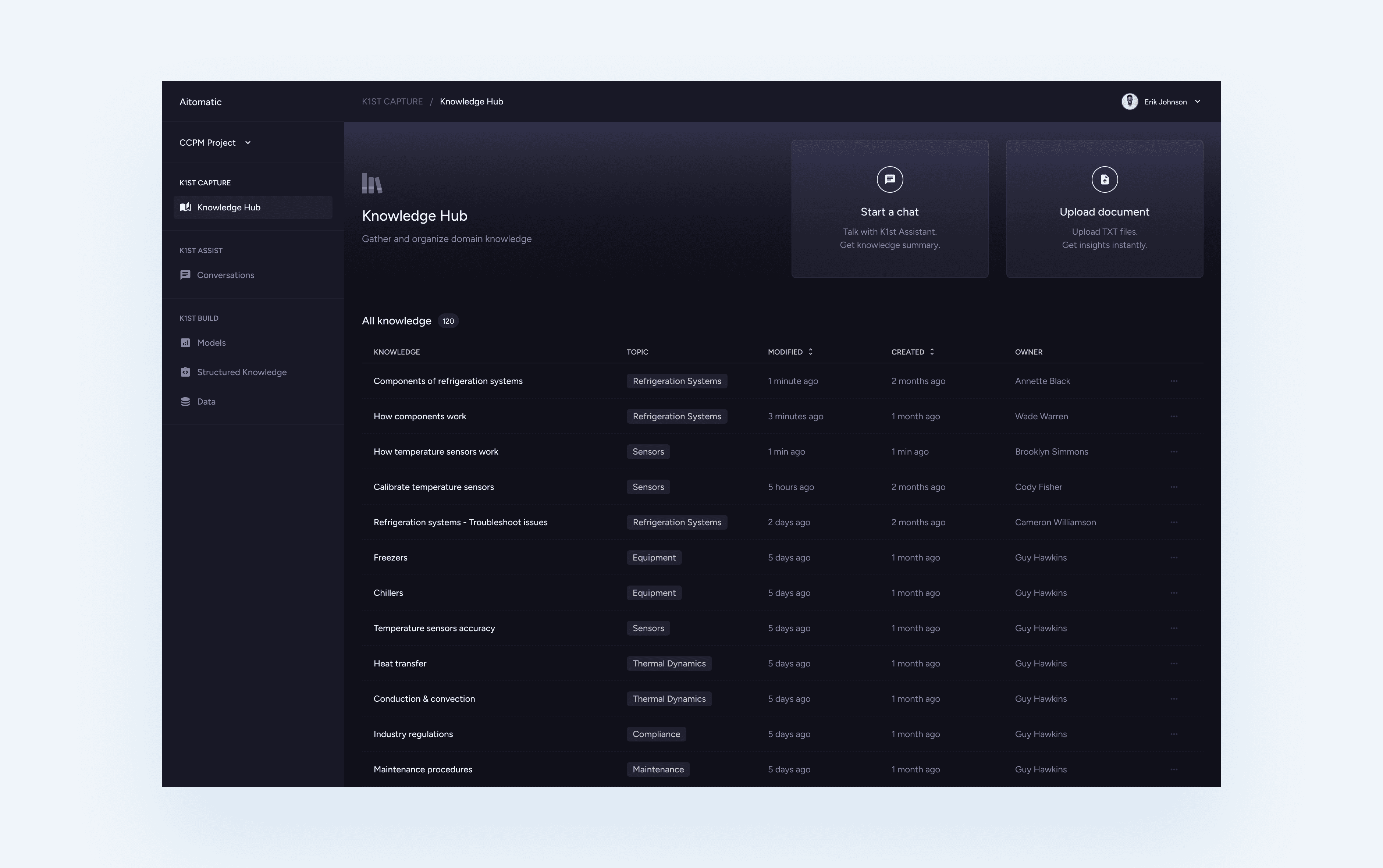

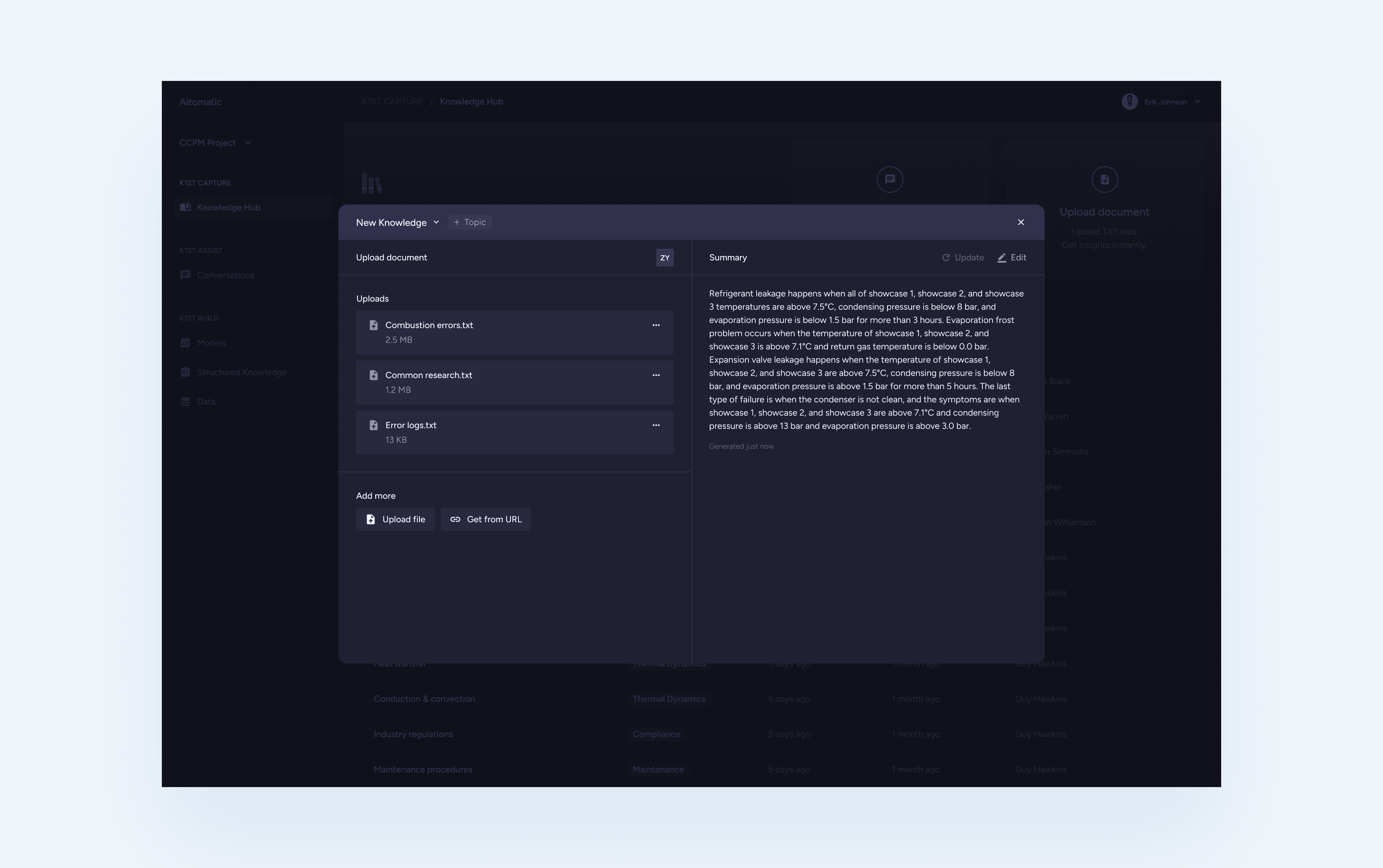

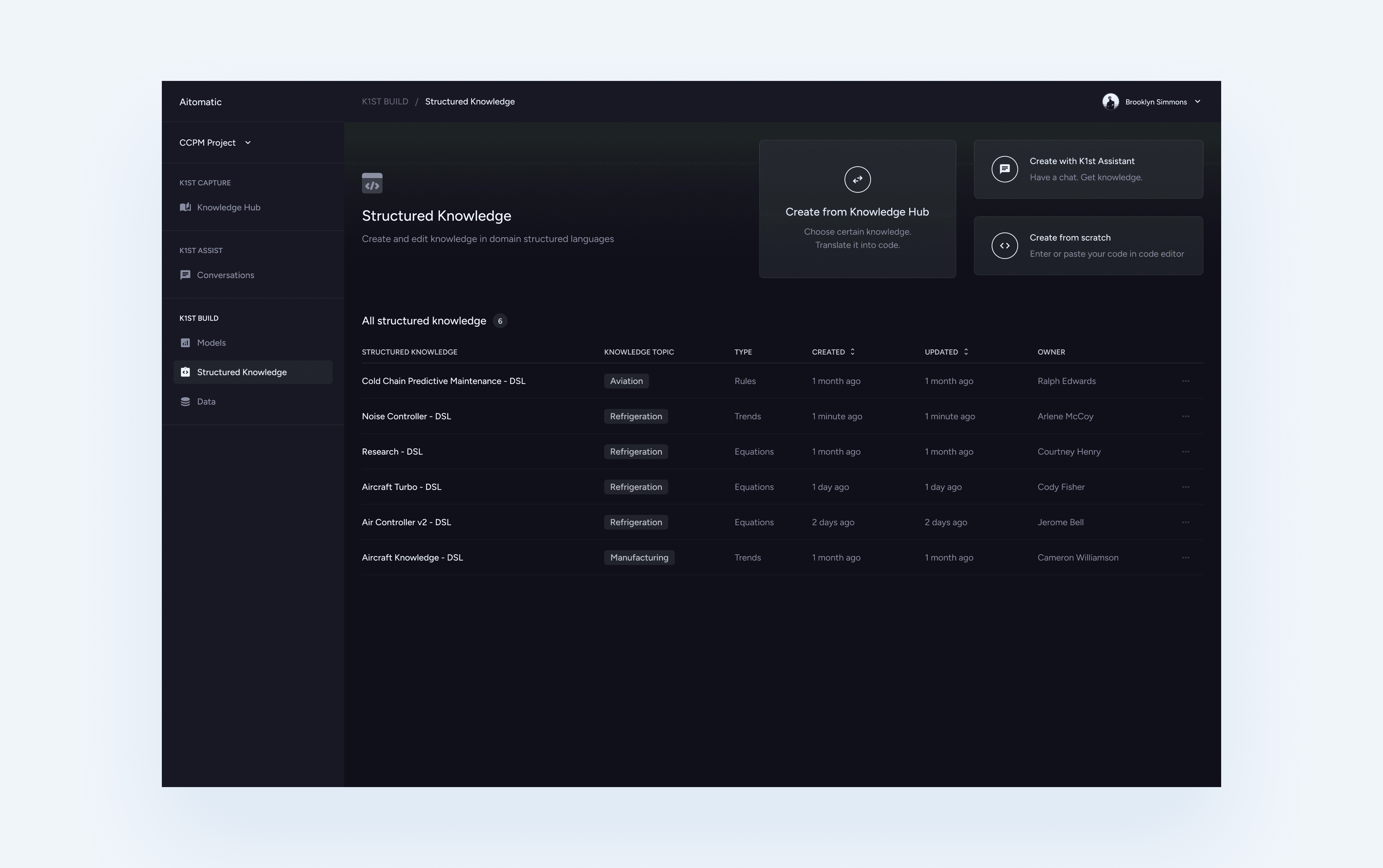

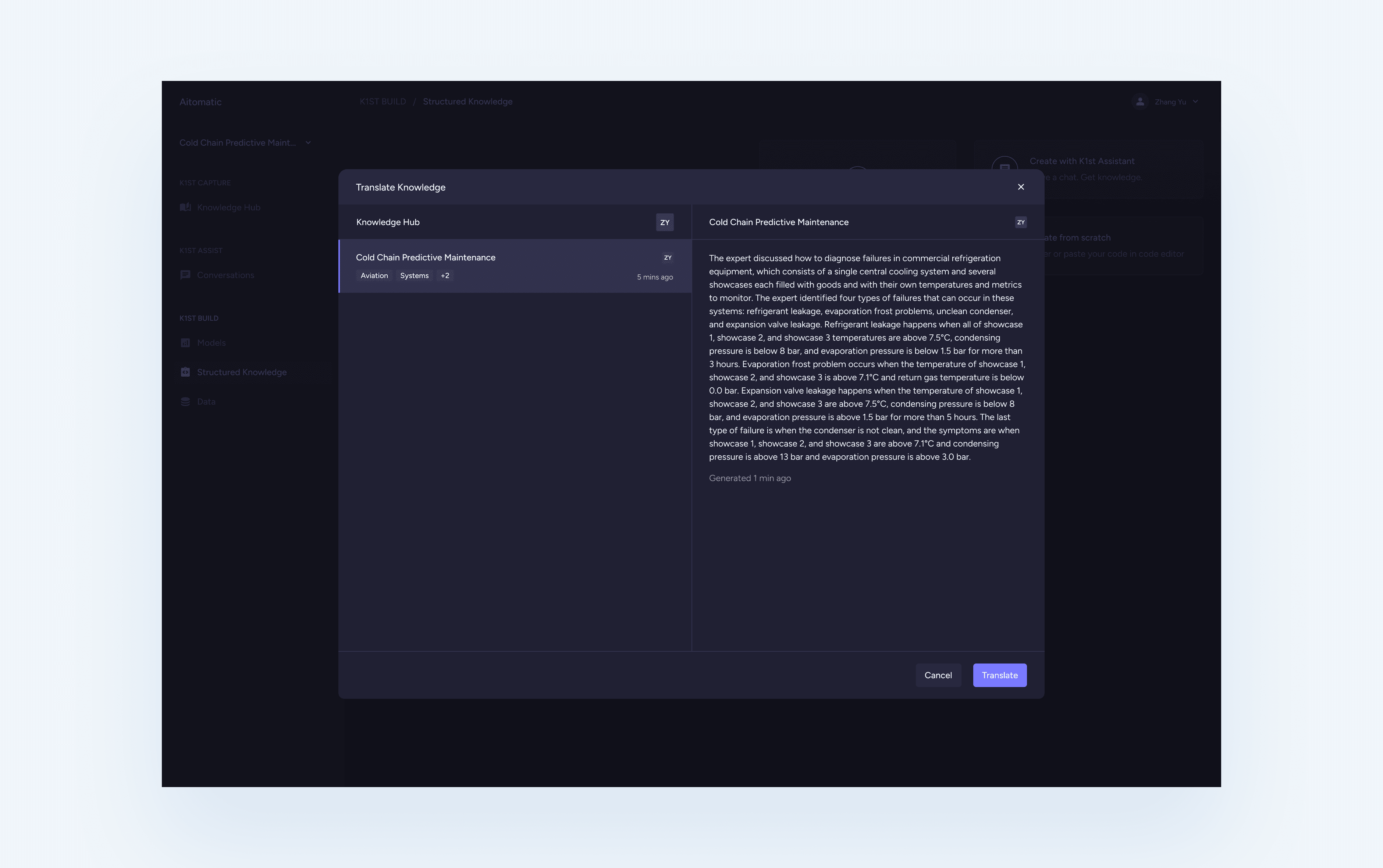

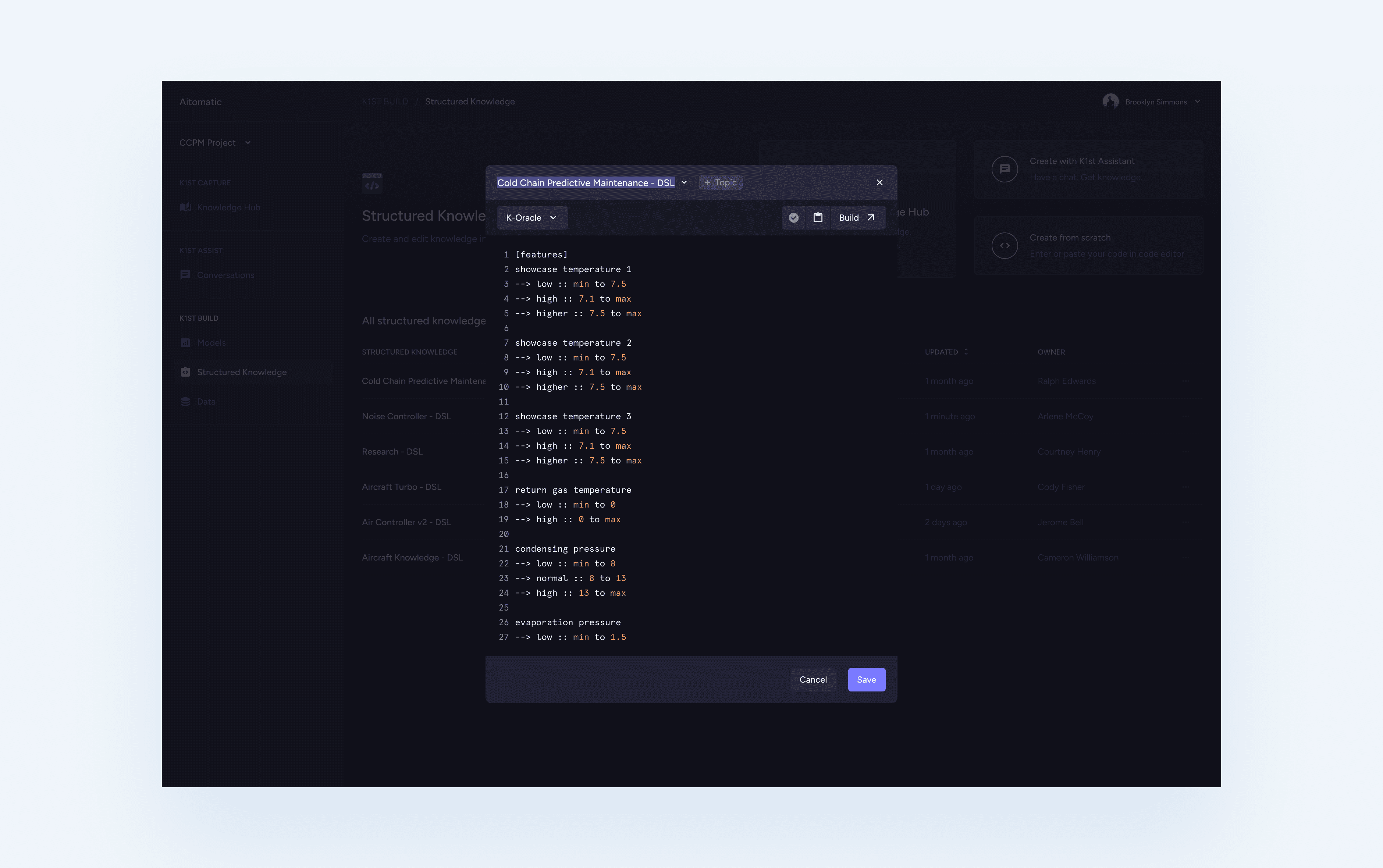

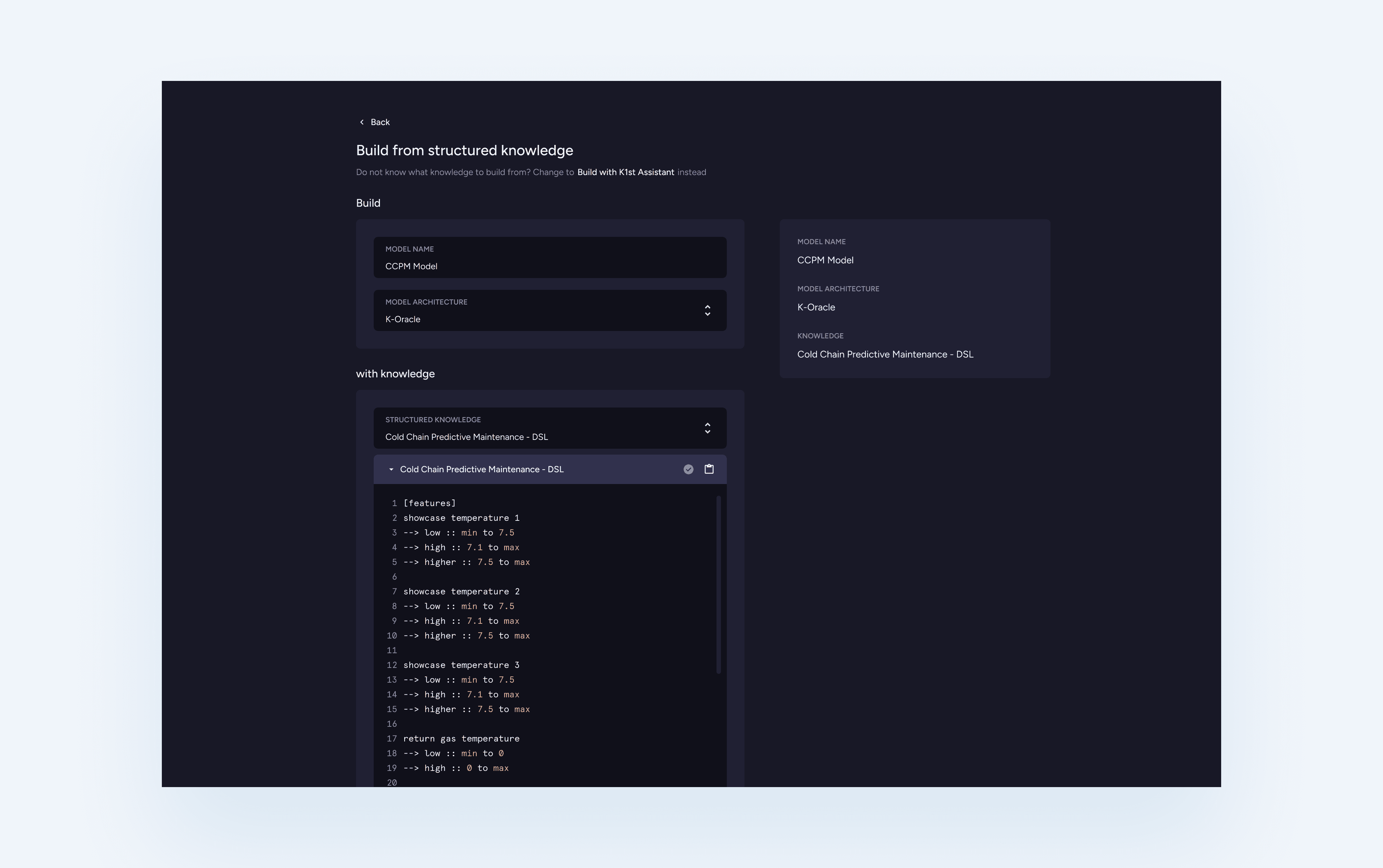

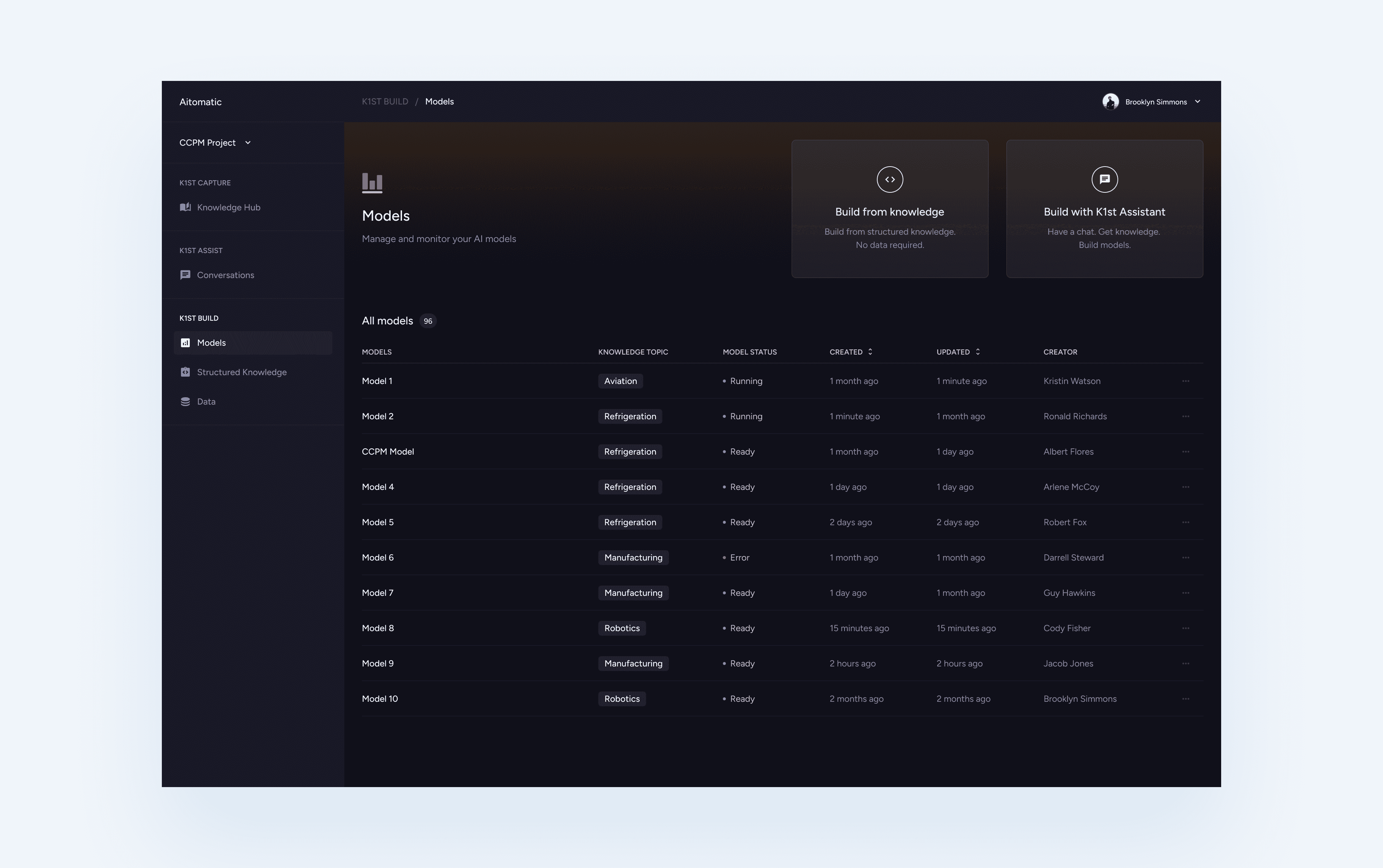

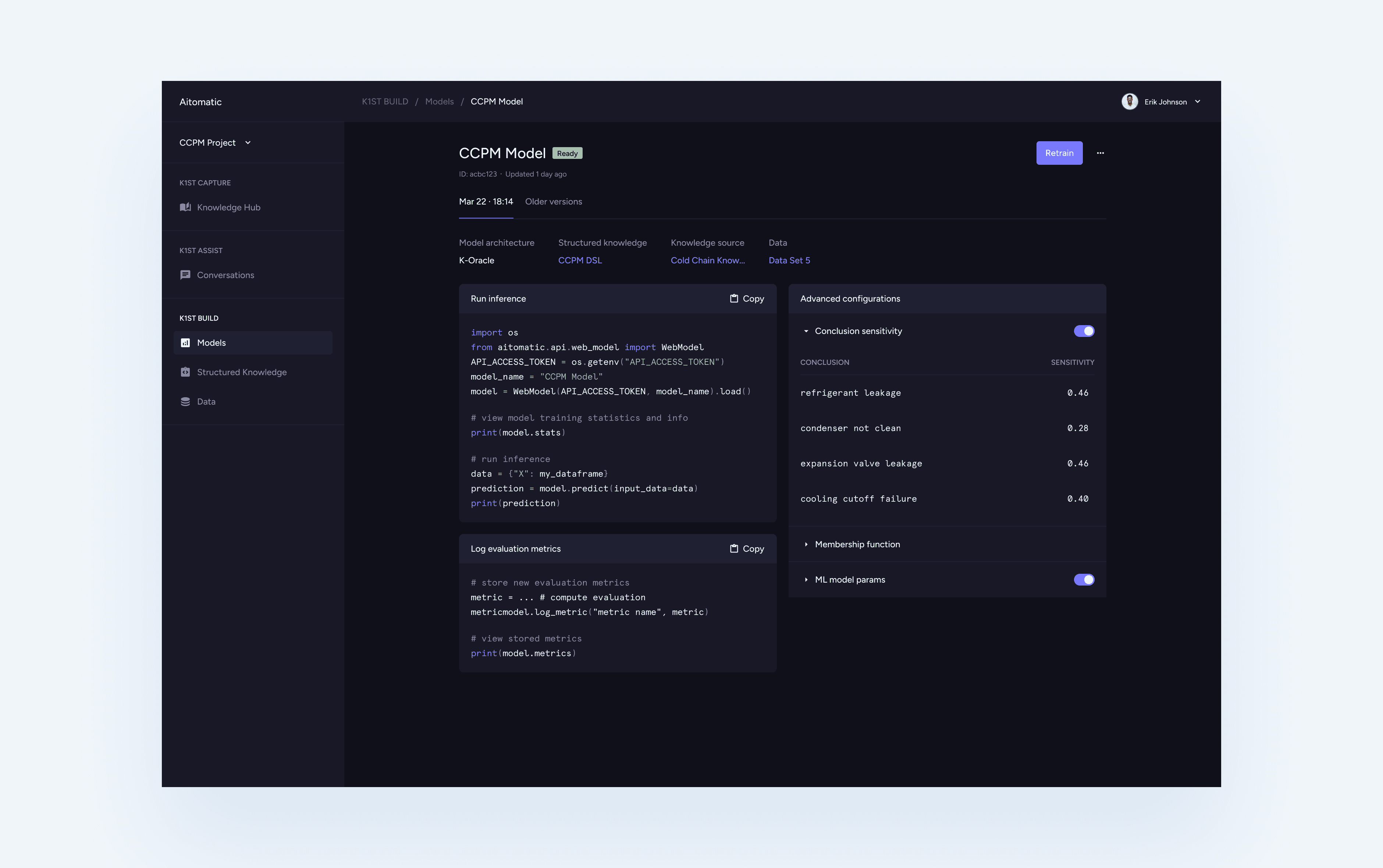

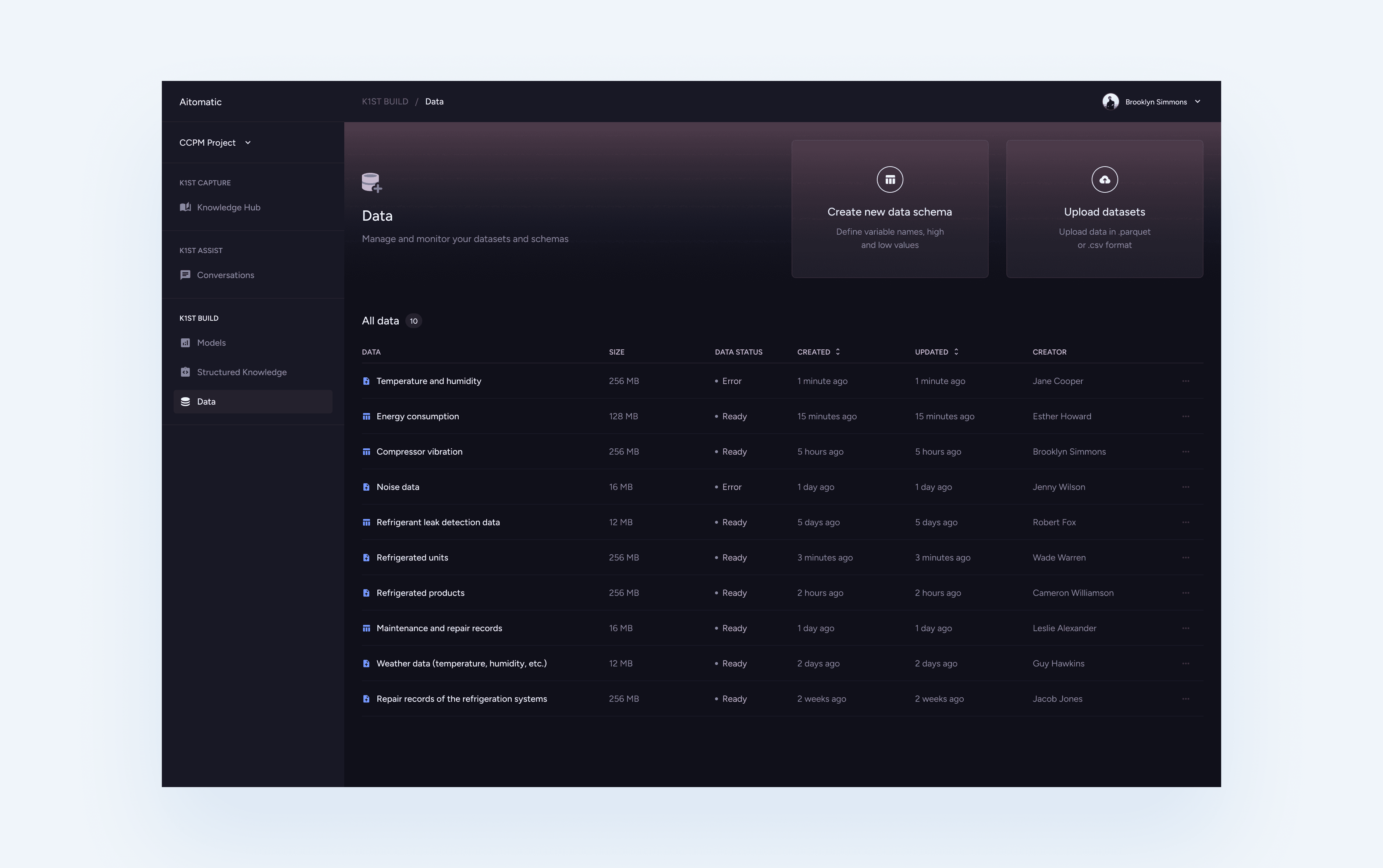

As the Founding Designer at Aitomatic, I led the design of K1st BUILD, a knowledge-first platform that utilized insights from domain experts in building models. Instead of relying solely on data, engineers could now use expert knowledge to fill in gaps, making model development faster and more accurate.

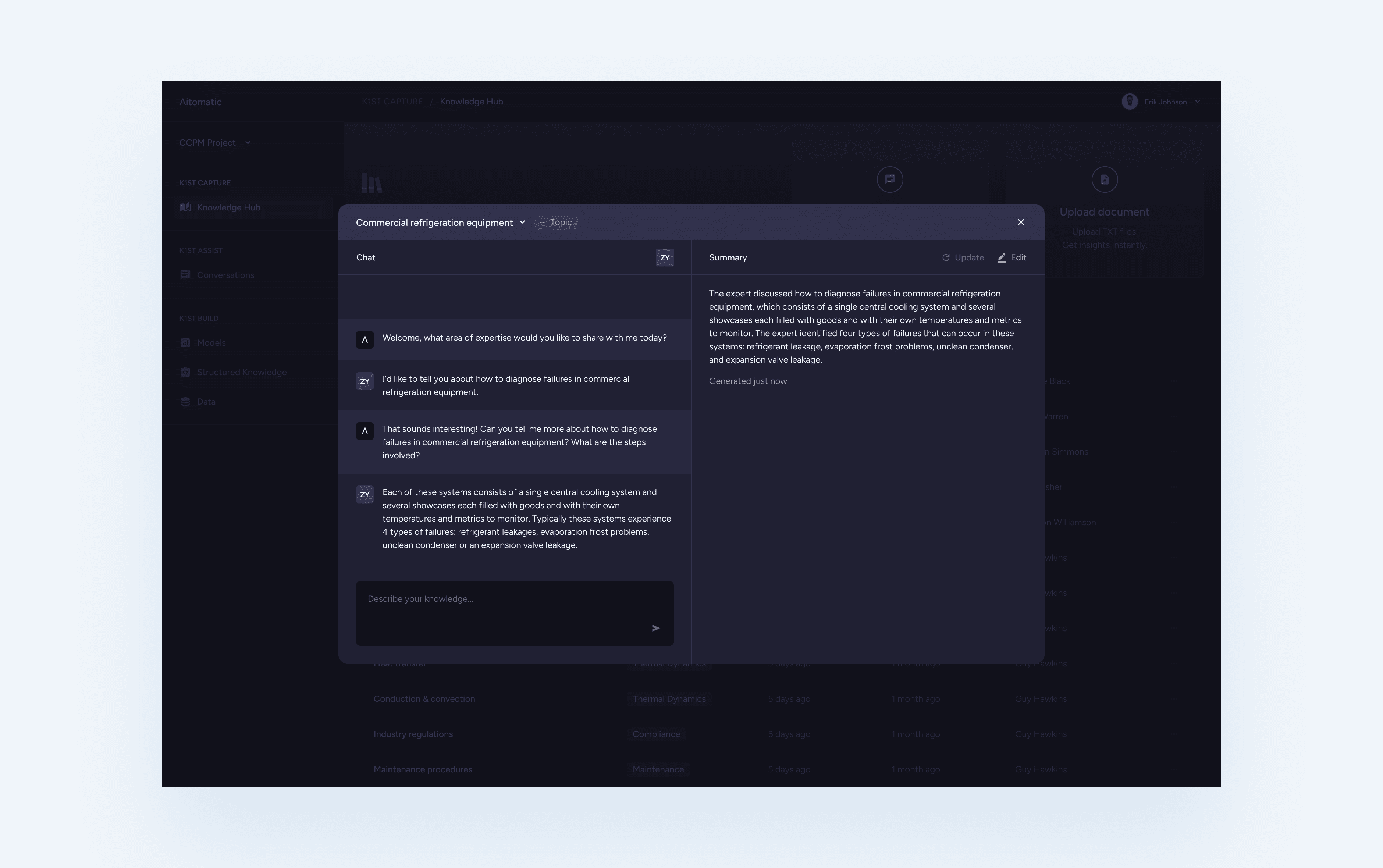

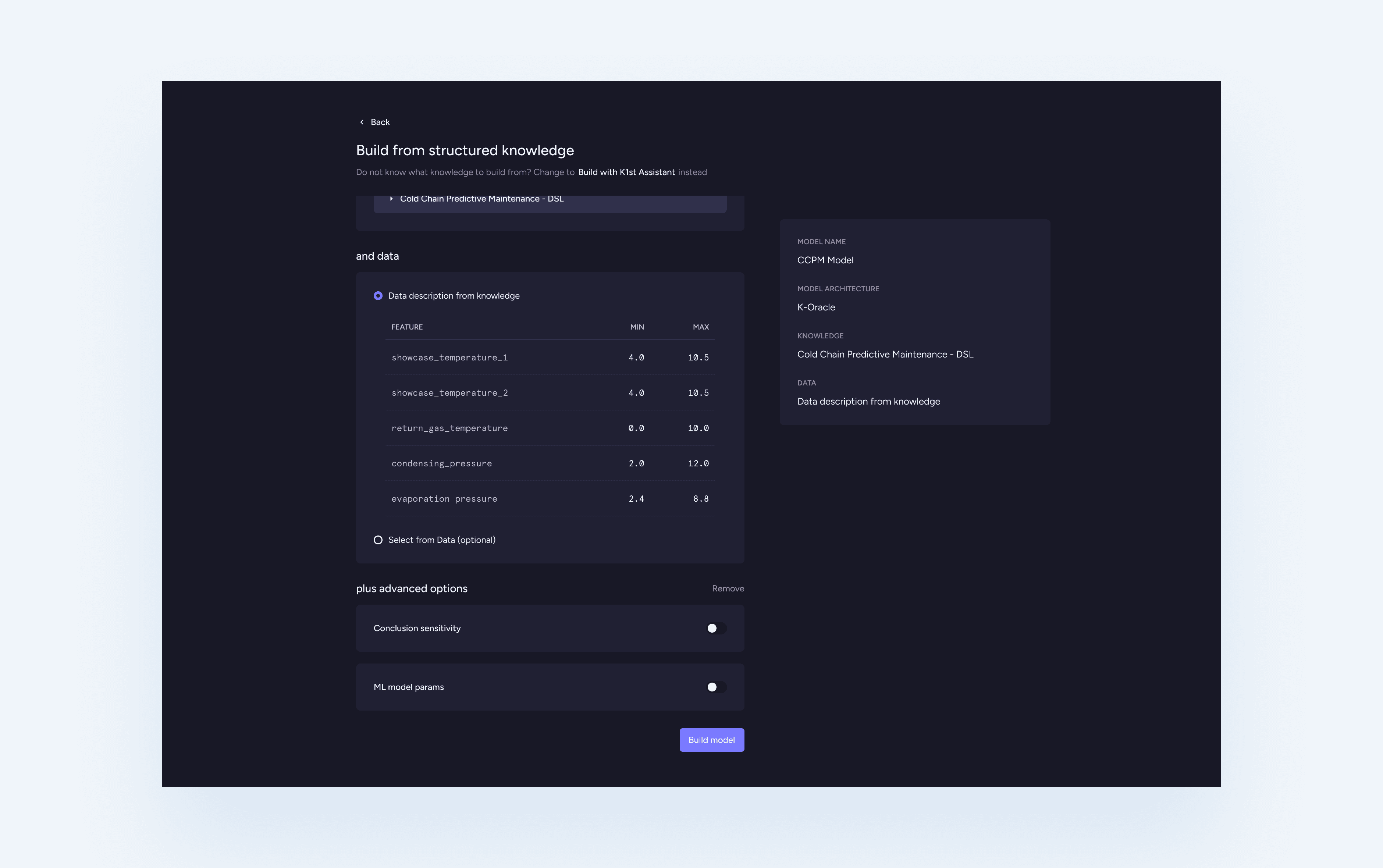

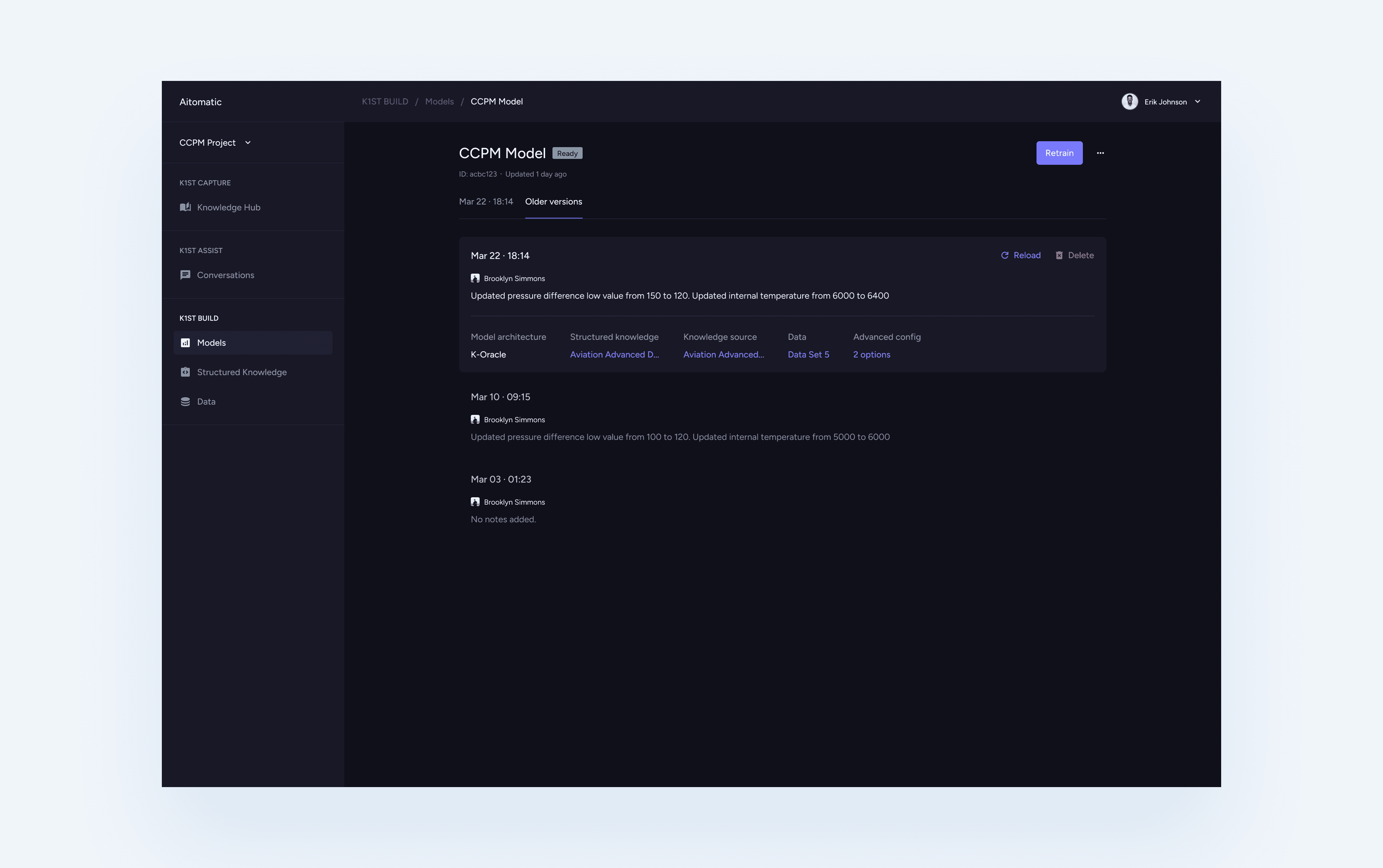

To make this vision real, I worked closely with CNA (a Panasonic Group company) and Aitomatic’s engineering teams to create a seamless experience. Experts could document their insights into structured, reusable components—essentially blueprints for engineers to integrate into AI models. Engineers, in turn, could adjust schemas dynamically and refine models on the fly, ensuring precision even with inconsistent data.

Testing revealed a critical gap: the flow between expert input and model development felt disconnected. I refined the experience to ensure insights transitioned effortlessly into AI workflows. Feedback loops between engineers and experts were also built in, creating a continuous cycle of validation and improvement.

Impact

K1st BUILD transformed the way manufacturing teams approach AI. By combining human expertise with structured workflows, we reduced data preparation time by 30%, enabling engineers to focus on model building instead of cleanup.

In predictive maintenance, model accuracy improved by 10–15%, delivering reliable results in weeks instead of months. Teams also reported a 20% improvement in alignment, as the platform enabled smoother collaboration between engineers and domain experts.