aiVA

AI advisor for gas refineries

Problem

Every hour of downtime in a gas refinery costs millions of dollars. Maintenance planners at Petronas felt overwhelmed and reactive with their planning tools.

Solution

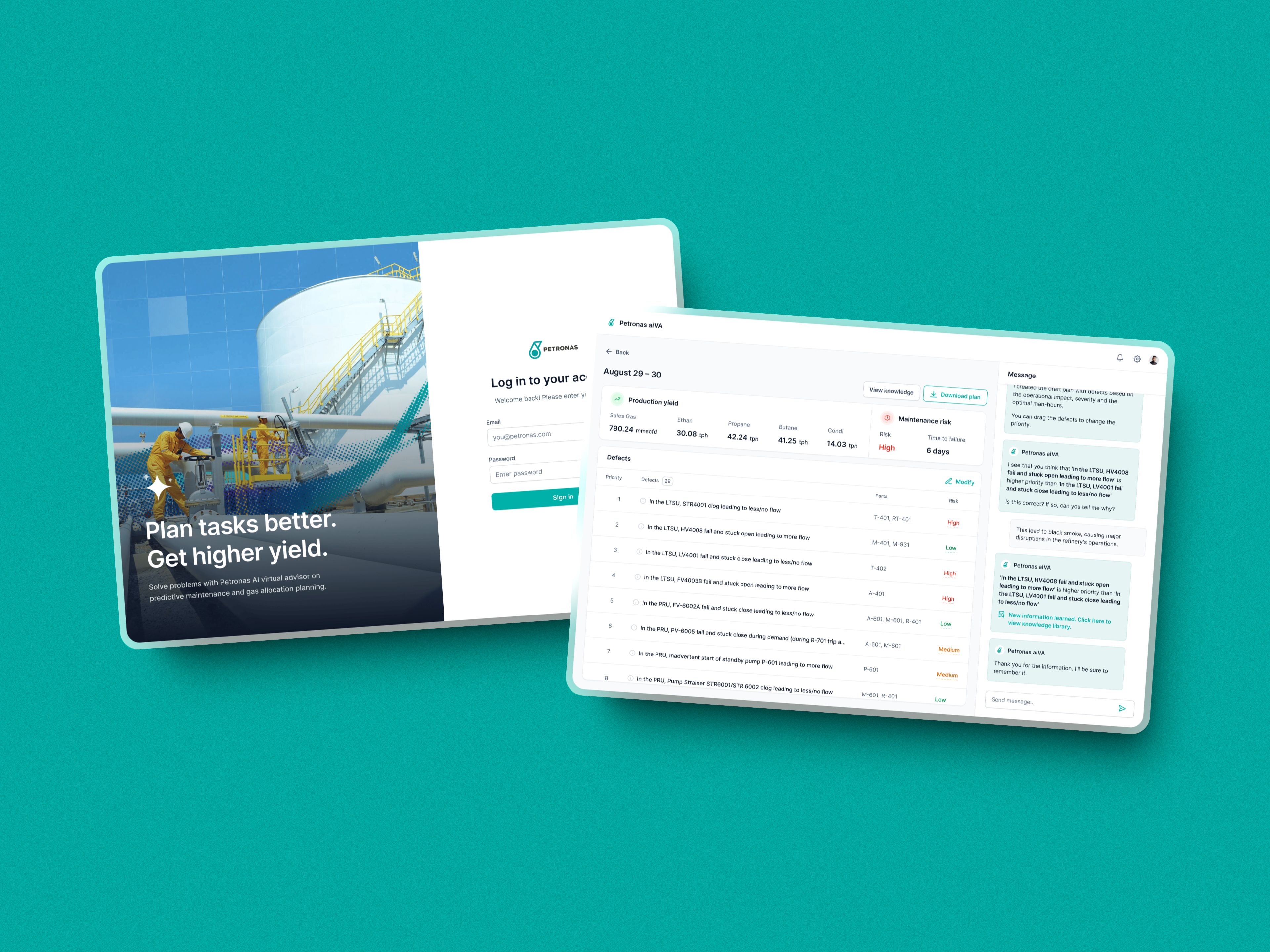

I led the design of aiVA, an AI virtual advisor that provided planners with clear, actionable insights and adaptive, real-time schedule recalibration.

Reduced task recalibration time by 50%

Gave gas refinery operators more confidence

Shift focus from chaos to proactive decision-making

Company

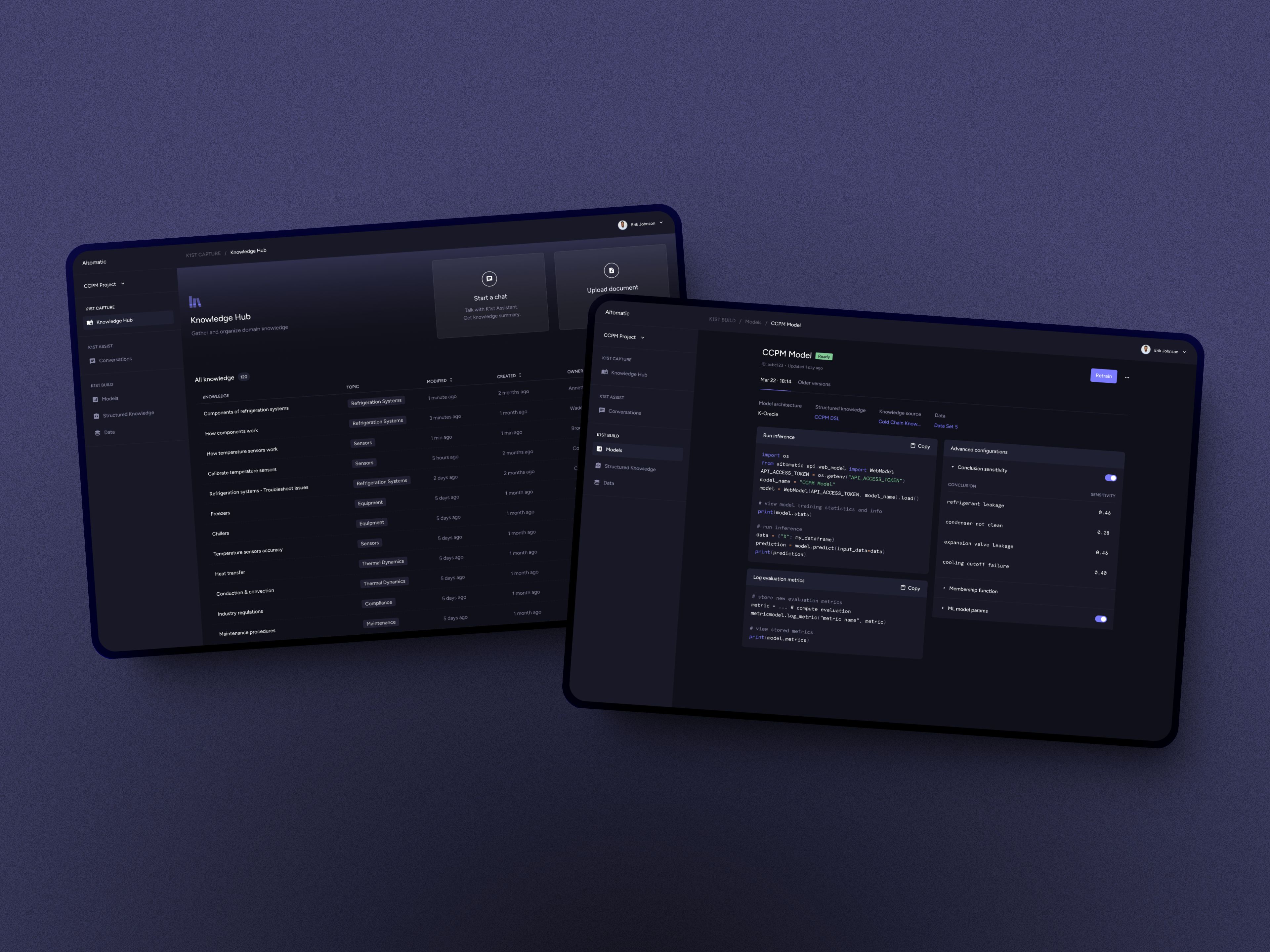

Aitomatic

Position

Founding Designer

Year

2023

Market

APAC, B2B

Problem

If you’ve ever been on a sinking ship, you don’t think about why the ship is sinking—you just patch the holes as fast as you can.

For maintenance planners at Petronas’ gas refineries, that was every day. A single hour of downtime could cost millions, and planners were responsible for managing hundreds of interdependent tasks—fixing defects, coordinating teams, and keeping everything running.

But when a defect appeared, the tools they used didn’t help. Planners were left recalculating everything manually, shifting tasks like dominos and hoping nothing collapsed. The system gave no answers—just endless data and decisions made on instinct.

What we made

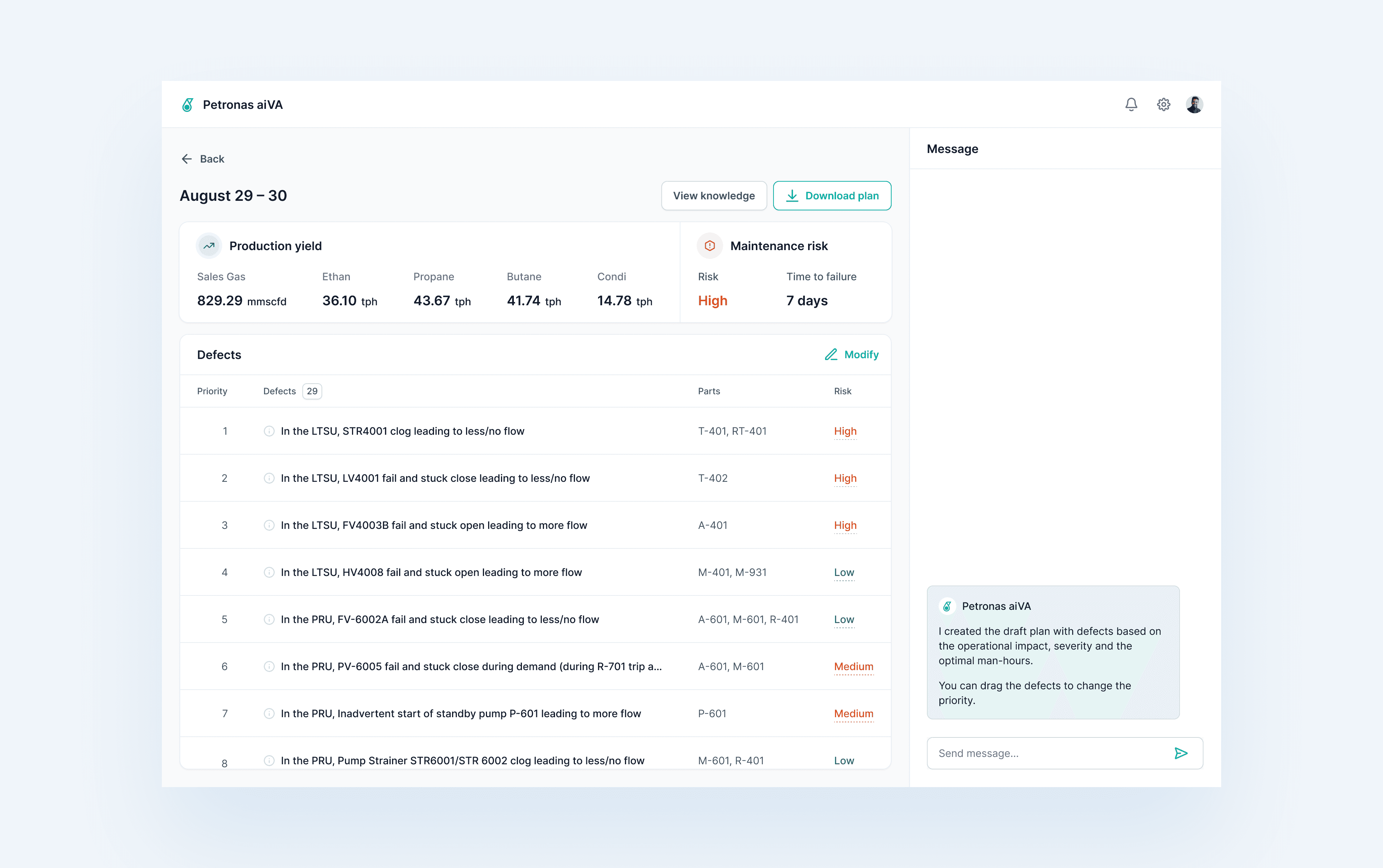

As the founding designer at Aitomatic, I designed aiVA, an AI virtual assistant that helps planners see what matters, act faster, and stay in control.

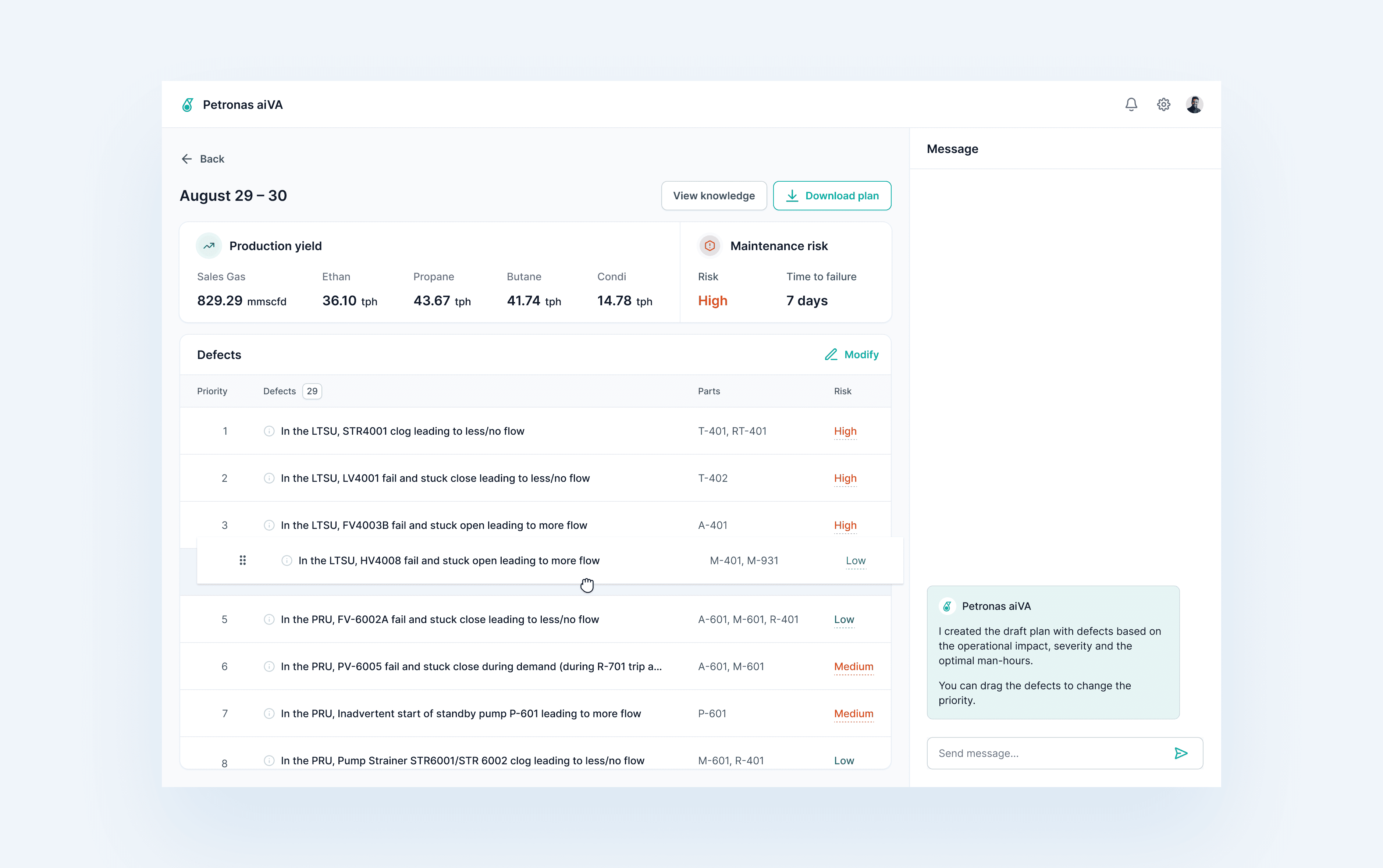

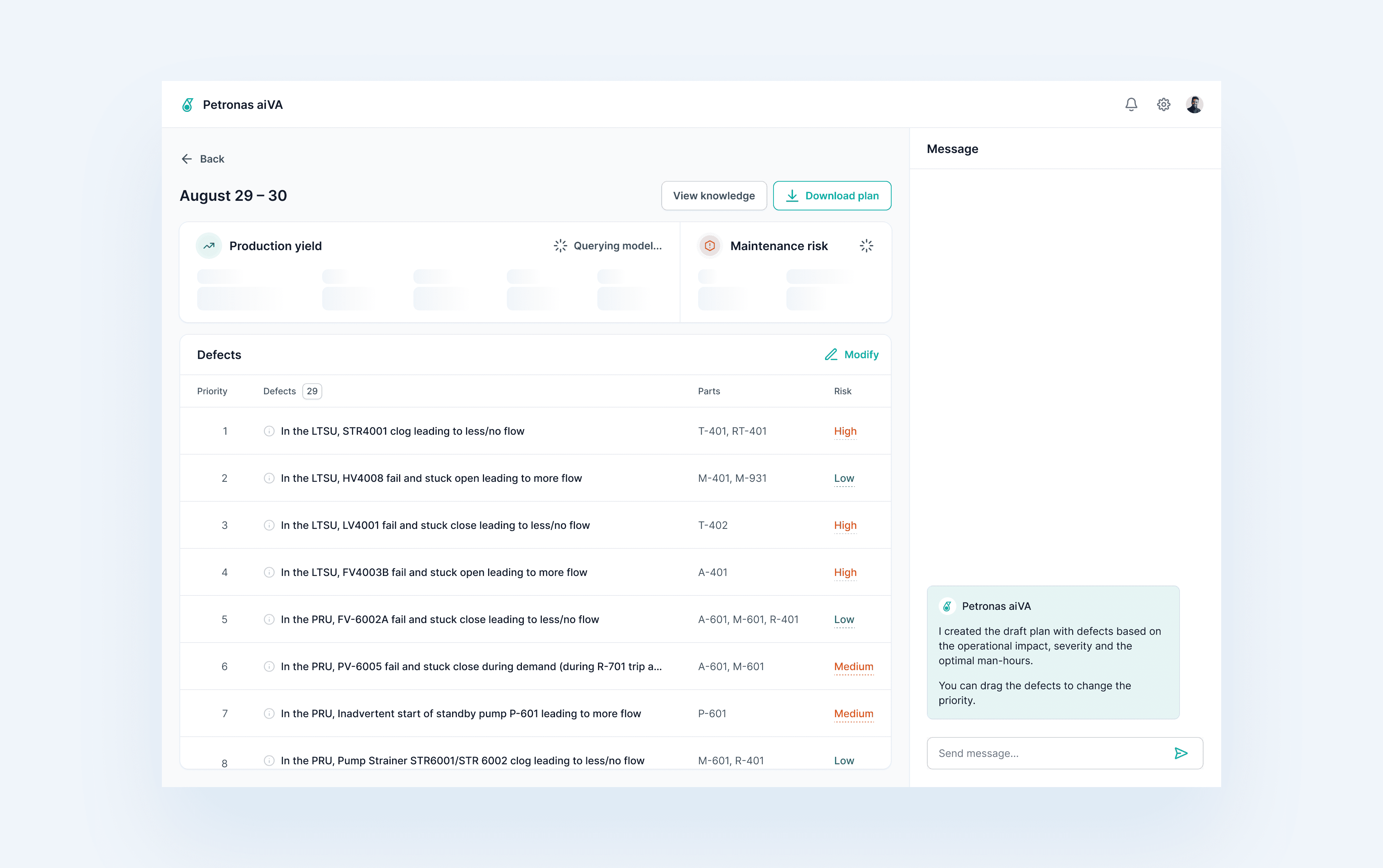

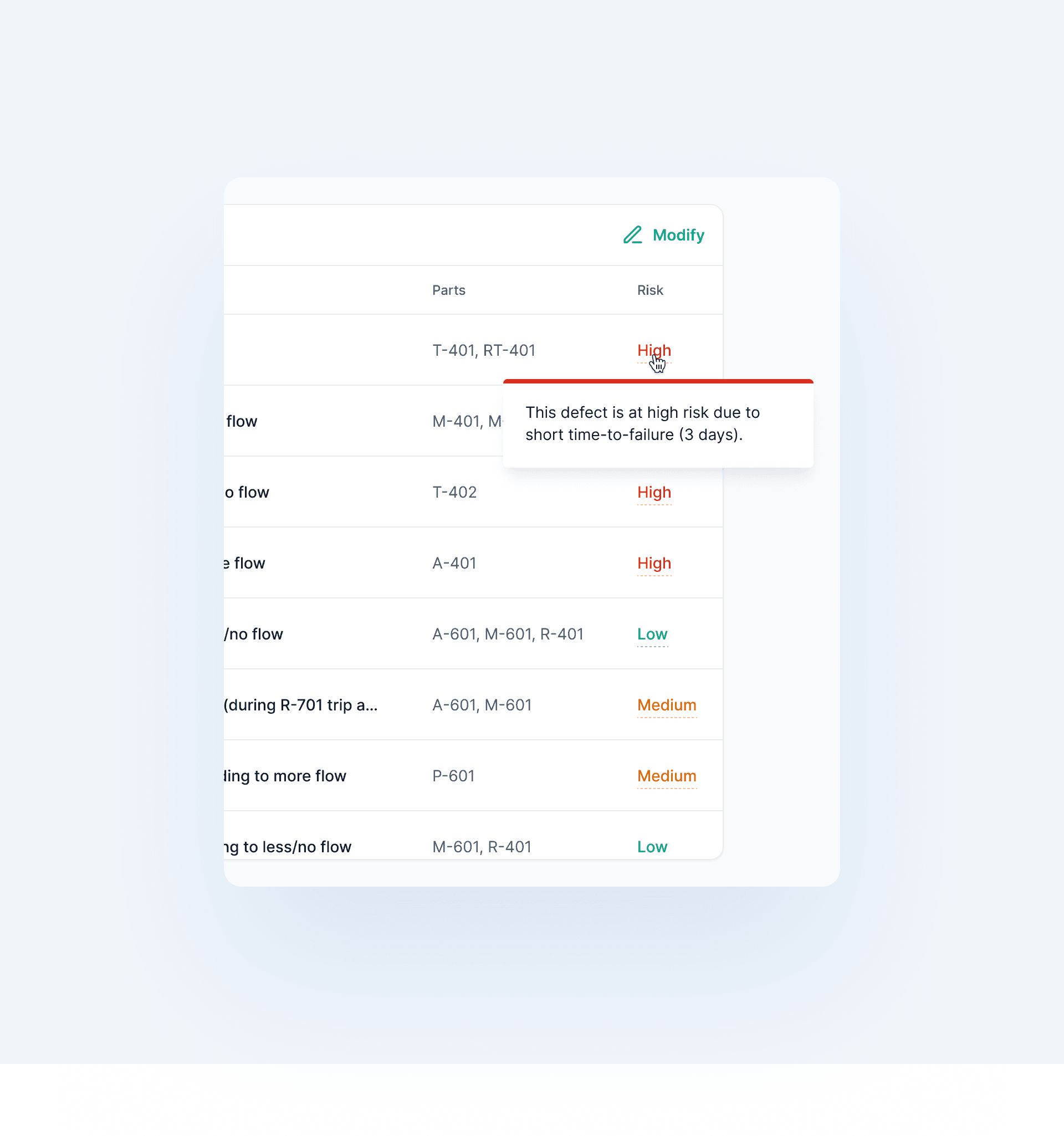

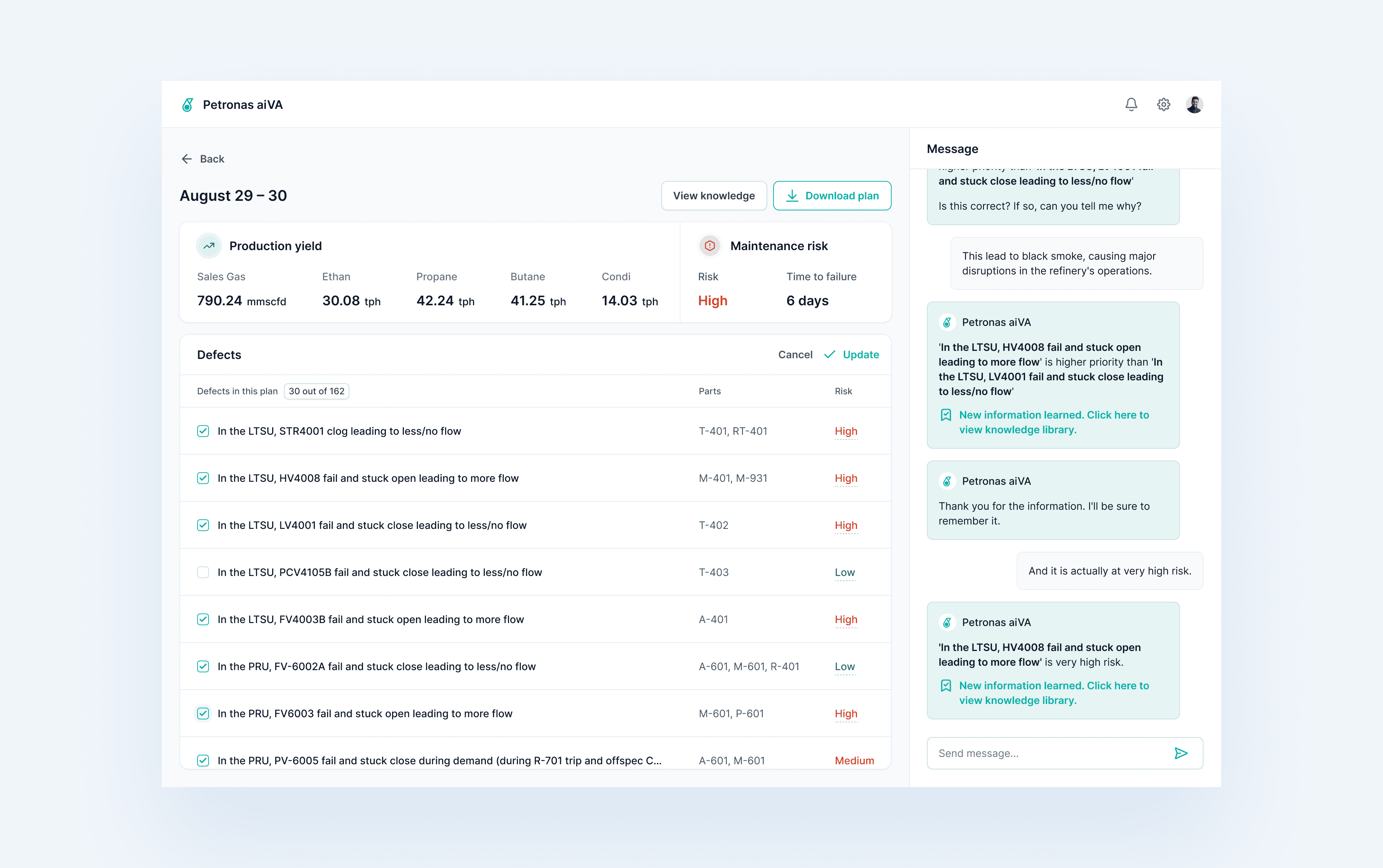

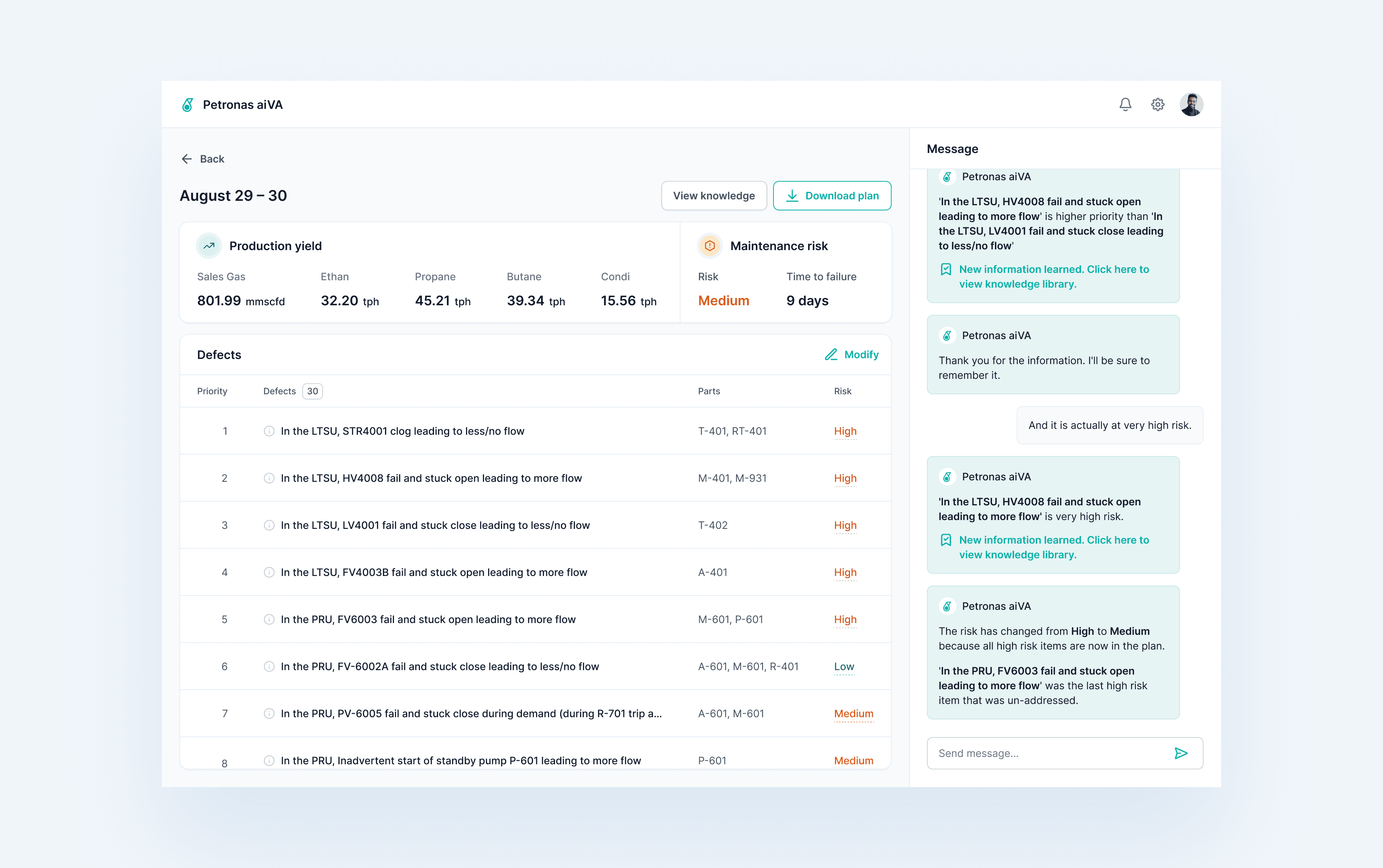

If a defect appears, aiVA flags the issue and explains why it matters. For example: “This defect impacts throughput in GPP3. If unresolved, you’ll lose 50 MMSCFD of production, costing $100,000 in the next 12 hours.” When priorities shift, aiVA recalibrates schedules in real time. No more guesswork—planners see instantly how changes impact timelines, costs, and risks.

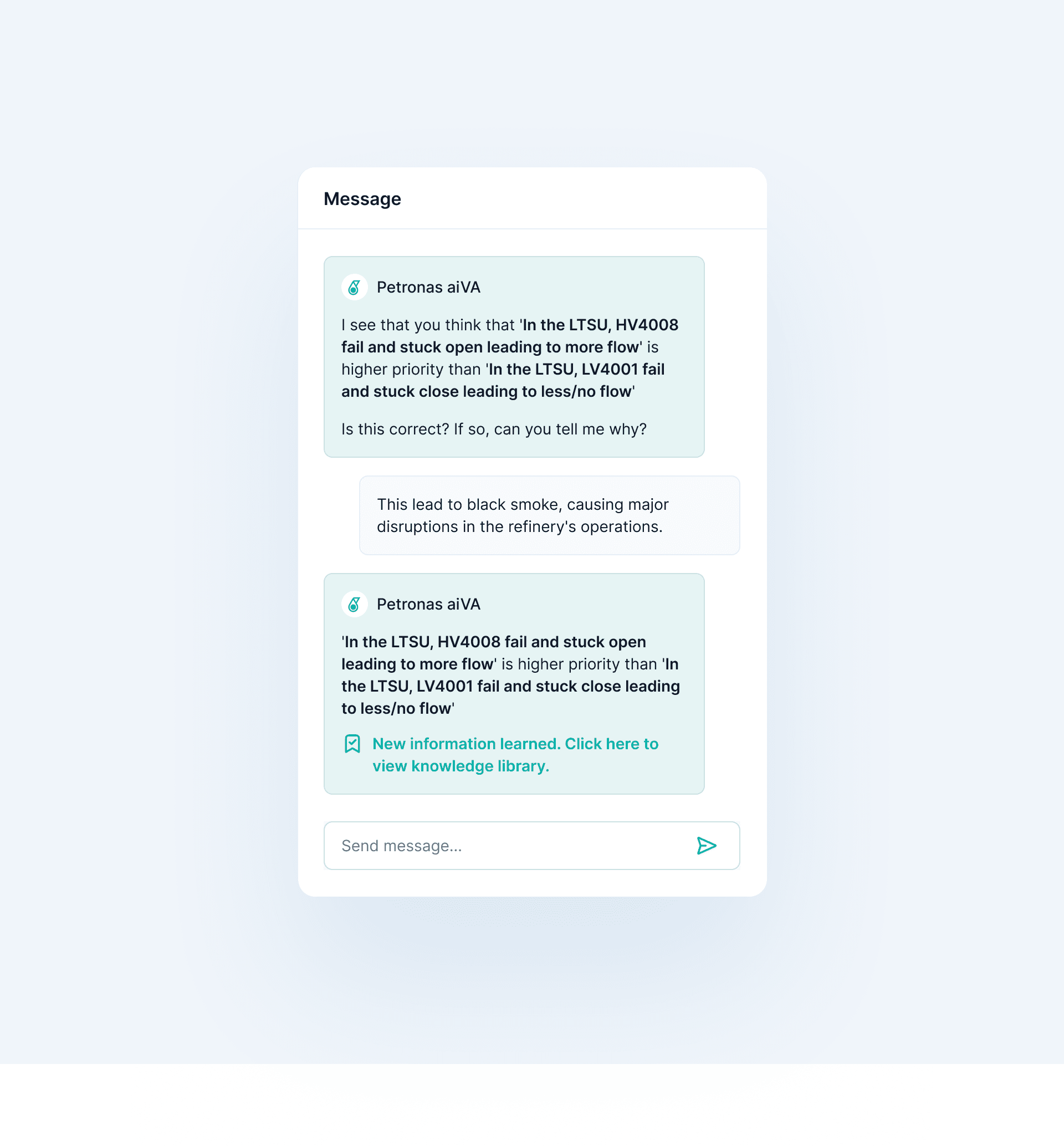

Over time, aiVA learns. Planners input their expertise—prioritizing certain defects or adjusting risk factors—and the system turns that into a shared resource, accessible to the whole team.

How we got there

As the design team of one, I led the end-to-end process, from research to final UI design while collaborating closely with the Head of Product and the broader Aitomatic team.

I started by studying with Petronas’ planners' workflows and listening to their frustrations. Through workshops and mapping exercises, I uncovered three critical needs:

Tools that explain their reasoning, so planners could trust the recommendations.

The ability to adapt quickly when priorities changed, without manual recalculations.

A shared knowledge system to make senior engineers’ expertise usable for everyone.

These insights drove aiVA design. I prioritized transparency and usability, when every recommendation backed by clear explanations. Early testing showed where planners got stuck, so I refined interactions to ensure the system fit seamlessly into their workflows.

Impact

Early tests showed that aiVA reduced task recalibration time by 50%, giving planners hours back to focus on preventing downtime rather than reacting to it.

One planner described it best: “aiVA gave us clarity where we used to feel lost. It’s like having an expert partner who helps you stay in control, even when everything changes.”

Petronas now has a path to scale aiVA across more refineries, transforming maintenance processes into something proactive, reliable, and cost-effective.