aiVA

AI-driven maintenance planning for gas refineries

Problem

Every hour of downtime in a gas refinery costs millions of dollars. Maintenance planners at Petronas felt overwhelmed and reactive with their planning tools.

Solution

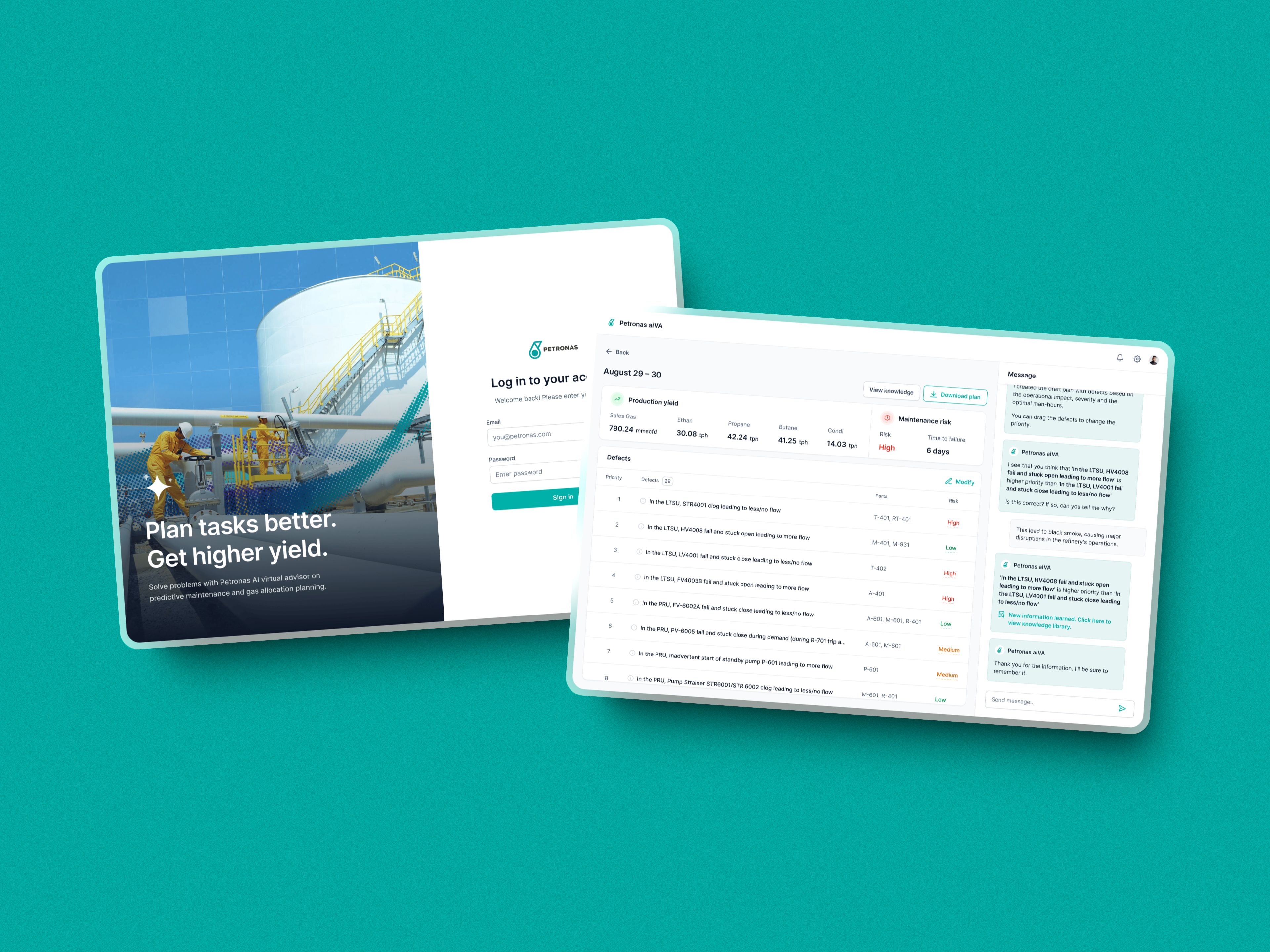

I led the design of aiVA, an AI virtual advisor that provided planners with clear, actionable insights and adaptive, real-time schedule recalibration.

Reduced task recalibration time by 50%

Gave gas refinery operators confidence

Shift focus from chaos to proactive decision-making

Company

Aitomatic

Position

Founding Product Designer

Year

2023

Market

APAC, B2B

Problem

Every hour a gas refinery stands idle costs millions. At Petronas, maintenance planners faced pressure managing hundreds of urgent, interdependent tasks. Their planning tools flooded them with endless data but offered no direction or priority. Each decision, whether to shift limited man-hours or leave a defect temporarily unfixed, carried operational and financial risks.

When Petronas partnered with Aitomatic to build a new solution, my role as the Founding Product Designer was to turn overwhelming complexity into actionable clarity through design.

Design principles

Planners told me: “We don’t need more data; we need clarity. Tell us exactly what we should prioritize, why it matters, and what will happen if we don’t.”

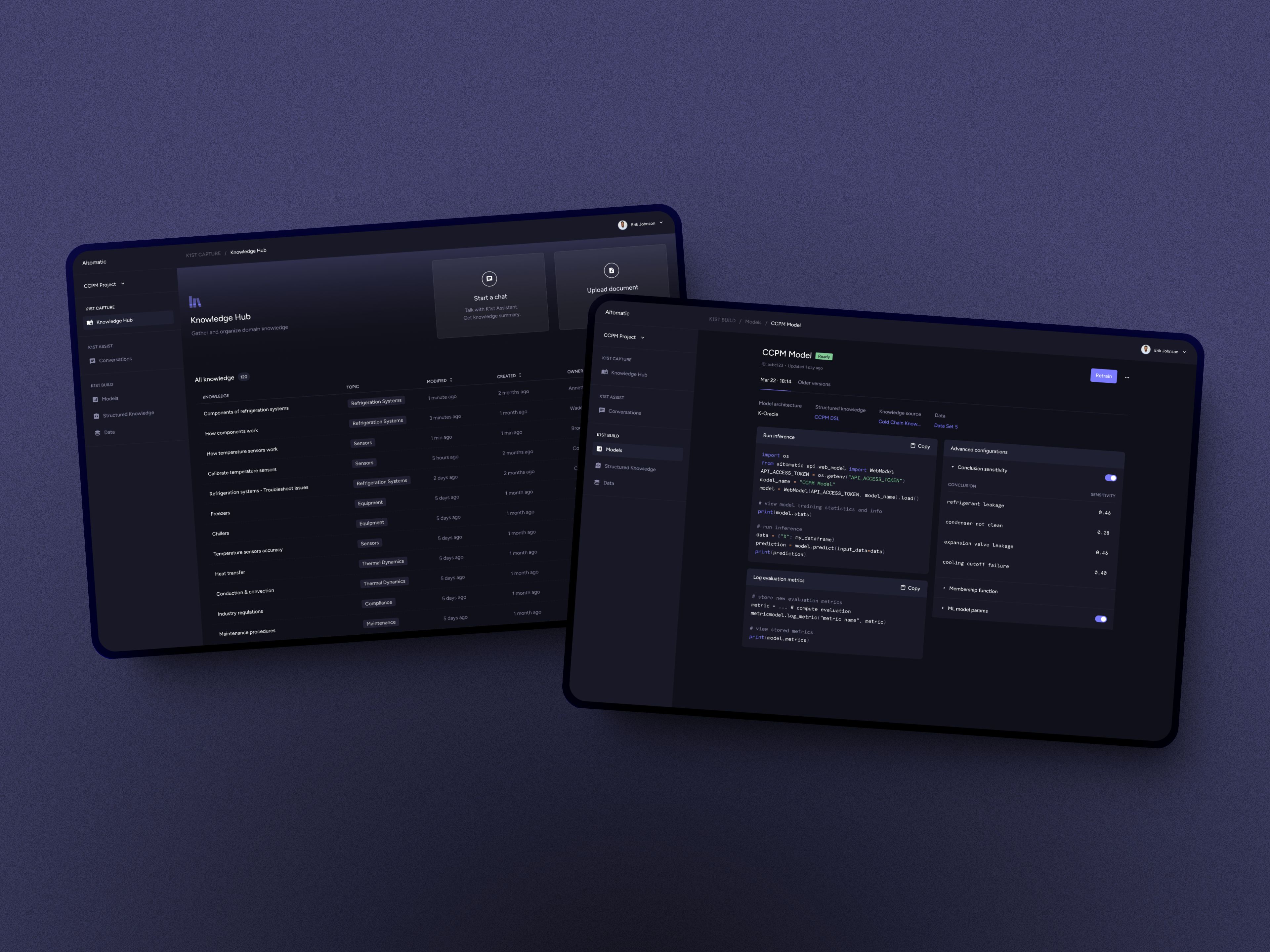

My approach centered on that level of clarity. The design must surface critical insights, freeing planners from data overload. Each recommendation from needed reasoning, tied to operational outcomes. Also, AI had to learn, capturing and scaling human expertise from each planner’s decisions while planners could proactively guide the system.

Design process

I talked with Petronas’ maintenance planners to conduct contextual research through interviews and workflow mapping exercises. These sessions revealed planners’ decision-making processes, hidden trade-offs, and unmet needs.

Based on these learnings, I ran workshops, prototyping sessions, and iterative design sprints with the Head of Product and the product-engineering team at Aitomatic. I translated AI functionality into simple and usable designs. Each iteration was tested and refined with stakeholders and planners, ensuring our app aligned with their real-world workflows.

What we built

The result was aiVA: an intelligent virtual advisor crafted to reduce cognitive load and enhance decision-making speed.

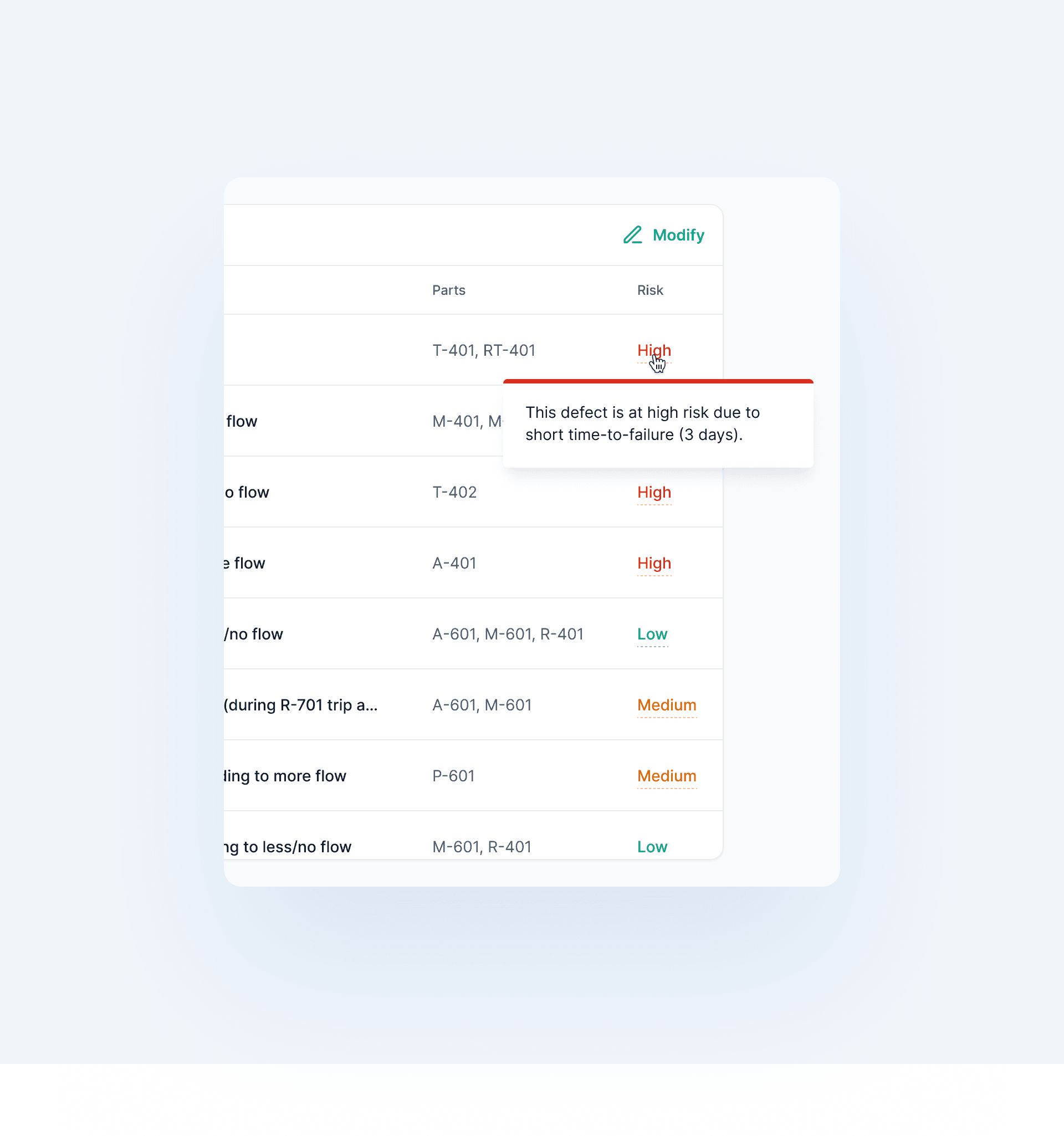

Whenever a defect appeared, aiVA presented planners with actionable recommendations. It explained potential impacts in precise terms. For example, aiVA might say: “If this defect in Gas Processing Plant 3 remains unresolved, production losses could reach 50 MMSCFD, costing approximately $100,000 within the next 12 hours.”

Beyond highlighting risks, aiVA recalibrated the entire maintenance schedule whenever priorities shifted. Planners could visualize how changes impacted timelines, costs, and operational risks, shifting from guesswork to proactive strategy.

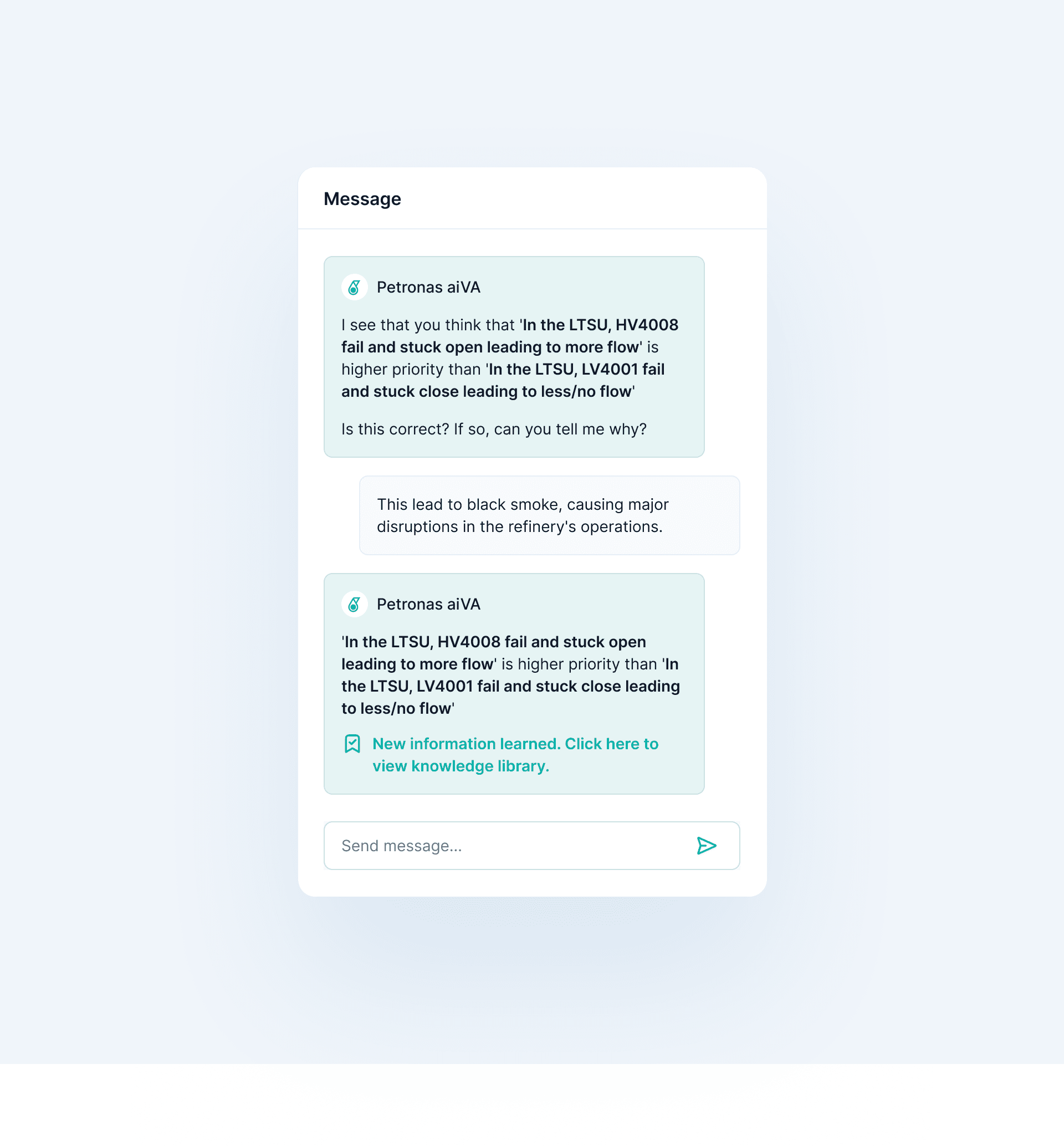

To foster future improvement, I and the team designed a human-in-the-loop interaction model. Planners could contribute their reasoning and correct AI decisions. aiVA captured human inputs to refine its knowledge base, turning planner expertise into a shared team-wide resource.

Impact

Early tests of aiVA demonstrated a 50 percent reduction in task recalibration time, giving planners more hours to focus on preventive measures rather than reacting to crises. Planners reported that aiVA provided the clarity of an expert partner, guiding them in prioritizing critical tasks without overwhelming them with data.

This success positioned Petronas to confidently scale aiVA across more refineries, changing maintenance operations from cost-centers into efficient and reliable assets.